Parameters

| Model | Automatic brushing and twisting machine (3 brushes)LJL-023 |

| Air pressure | 1.5-2.5kg/c㎡ Built in pressure regulating valve |

| Voltage Power | AC 220V 50-60Hz 10W |

| Air pressure | 4-6Kg/cm2 |

| Twisting speed | 1400circle/s |

| Twisting length | 5—80mm (150mm customize) |

| Wire range | 0.1-2(m㎡) |

| Dimension | 320*320*210mm |

| Weight | 15KG |

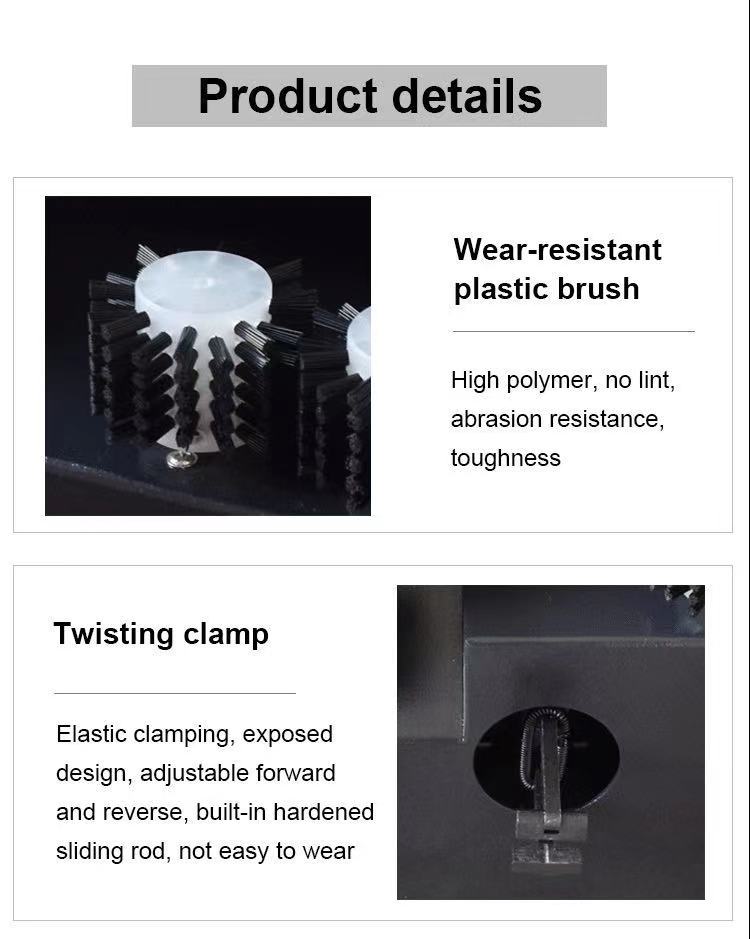

| Brushing motor | 12v 3000circle/s |

| Brushing wire range | 0.1-10mm |

| Brushing stripped length | 1-60mm(can be brushed up to 80-100mm depending on material of wire) |

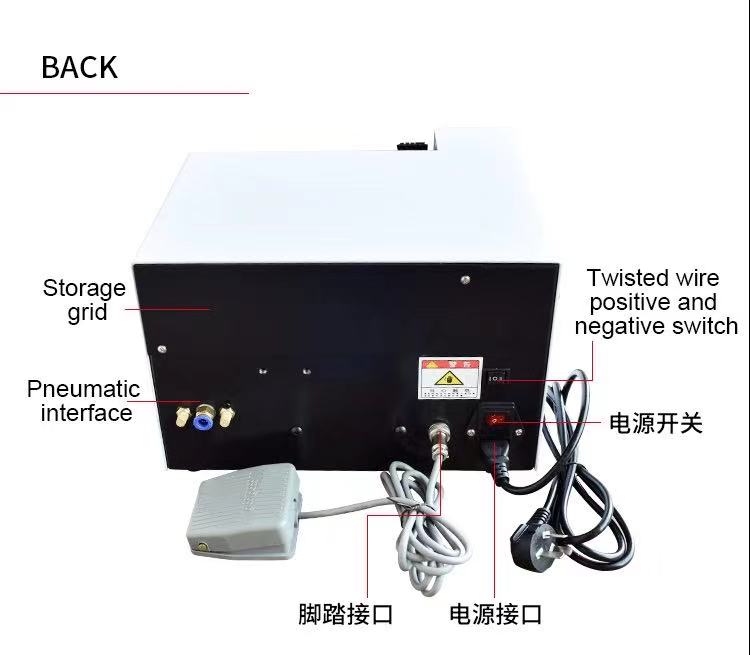

brushed to 70 square meters, and the length of shielding mesh can be brushed to 200 mm) Thread removal function: the outer diameter of the thread can be removed within 6 mm, the brushing length can be 0-60 (depending on the weaving density of the line of sight material), the brush wheel spacing can be adjusted, the speed of the thread removal wheel can be adjusted, and the stepless speed change can be realized, with a separate switch control. All kinds of ground wires, braided wires and isolation wires can be tightened, completely replacing manual work. The gripping hand adopts pneumatic control. When the air source is connected, the gripping hand will automatically open. When working, only need to hold the wire in, and lightly turn on the foot switch to complete the twisting operation.

brushed to 70 square meters, and the length of shielding mesh can be brushed to 200 mm) Thread removal function: the outer diameter of the thread can be removed within 6 mm, the brushing length can be 0-60 (depending on the weaving density of the line of sight material), the brush wheel spacing can be adjusted, the speed of the thread removal wheel can be adjusted, and the stepless speed change can be realized, with a separate switch control. All kinds of ground wires, braided wires and isolation wires can be tightened, completely replacing manual work. The gripping hand adopts pneumatic control. When the air source is connected, the gripping hand will automatically open. When working, only need to hold the wire in, and lightly turn on the foot switch to complete the twisting operation.